Sittvagn

Product Design / Design for Children / DFM / Cost Analysis

In hospitals, parents experience difficulties transporting young children around during an IV infusion. Apart from keeping their children entertained constantly, parents need to wheel both the stroller and the IV stand, as well as carry all necessary supplies.

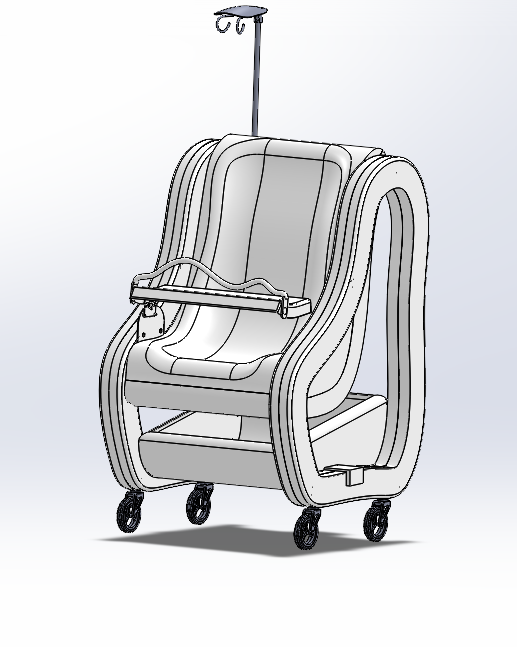

Sittvagn is a solution that eliminates the discordance between the patient’s stroller and IV stand during transport via the fusion of the two components.

(2022)

In-hospital Stroller with an iv stand Customer Needs

To uncover the needs on the market, we interviewed several parents to see what to take into consideration during the concept generation phase.

Essentials:

Durable

Comfortable

Ample Storage

Limited Access to Medical Supplies for Children

Critical:

Easy to Move

Easy Access to Medical Supplies for Caretakers

Needs:

Child friendly design

“The stroller should be aesthetically pleasing… Of course, it should have ample and accessible storage for kid’s stuff.”

“The most important thing for me is good, sturdy wheels”

“This device should look engaging, like something that comes out of a playground.”

Concept Development

We wanted to create a stroller that adapts an organic shape with considerations to human ergonomics. We thought the shape could be more attractive to small children and help them to get over their fears.

We took an initial shot at CADing a very rough “all in one” CAD model with Solidworks. We referenced the rough CAD moving forward in discussions about fine details of the model.

After many iterations, we were satisfied with how “Sittvagn” looked in the end.

To make our concept came alive, we rendered the design with vibrant colors.

IV Stand:

Maximized symmetry

Snap fit pole cover

Self-locating slider

Design For Assembly Considerations

Stroller Body:

Poka Yoke for frame alignment

Reduced part count by combining seat and back into singular part

Maximized symmetry

Self-aligning storage basket

CAD Exploded View & Process Design

Seat Frame: Material: ABS Color: Pantone 551 C | #A3C7D2 Process: Injection molded Draft: 1 degree Uniform Wall thickness

Seat: Material: Polyurethane Process: Molded Density: 0.03 to 0.05 G/CM3 Attachment: Adhesive

Basket: Materials: ABS Color: Pantone 11-0601 TPX Process: Injection Molded Draft: 1 degree Uniform Wall Thickness

Stroller Body

IV Stand top cover and base: Materials: ABS Color: Pantone PMS 373 C Process: Injection Molded Draft: 1 degree Uniform Wall Thickness

Pole: Material: Stainless Steel Process: Extruded

Handle: Material: Aluminum Process: Extruded

IV Stand

Product Specification

Cost Analysis

Overhead: 25% Total cost: (low/high): $ 79.47/$95.2

Cost Breakdown Model

Target Production Cost

Total cost: (low/high): $ 79.47/$95.2

Non-Recurring Model

Potential Cost Reduction Cost Analysis